Who We Are

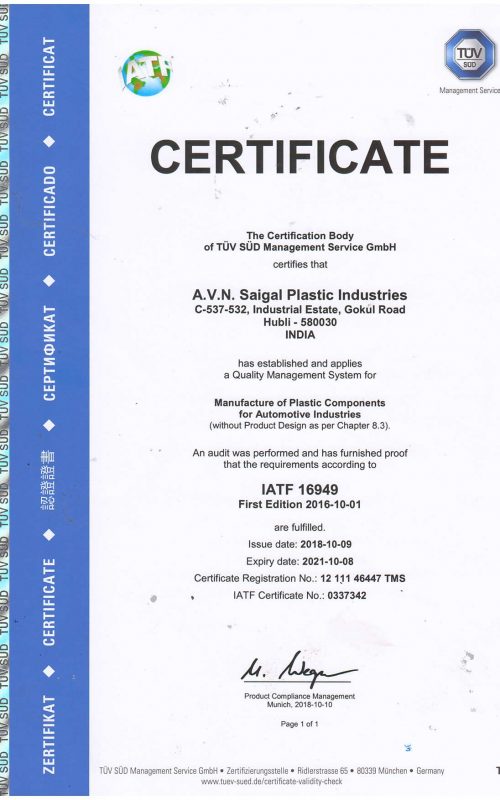

We, M/s. AVN SAIGAL Plastic Industries, a prominent supplier and manufacturer of plastic components for Automotive, Engineering and various other Applications, an IATF 16949:2016 certified Company with certification by TUV-SUD, Germany.

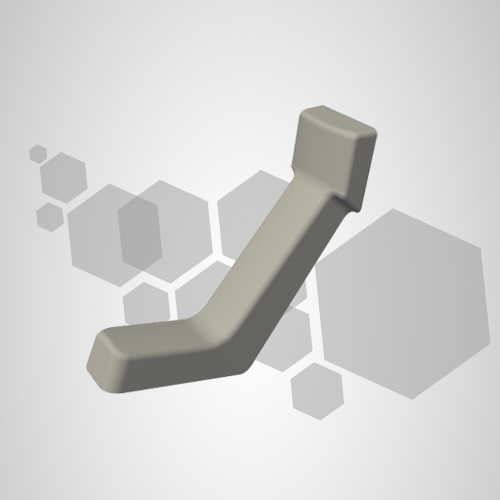

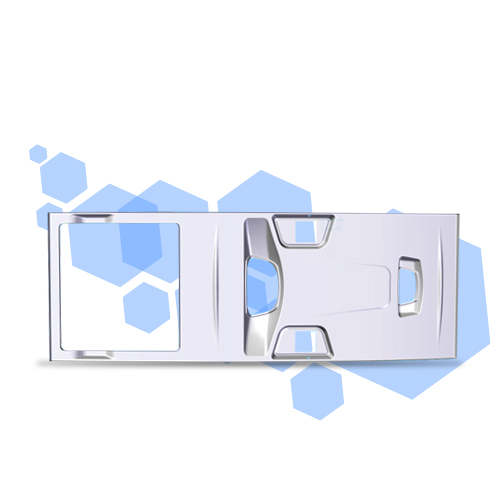

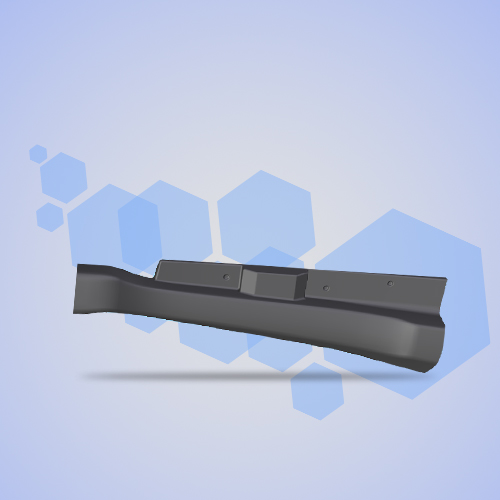

Vacuum thermoforming Process produces a Component that is seamless, strong, durable, lightweight and available in a variety of finishes. Vacuum formed parts are used in thousands of applications.

Thermoforming ( vacuum forming ) is the process of heating a two-dimensional plastic sheet, vacuum drawing it into a mold, and giving it an entirely new, permanent, three-dimensional form.

VACUUM THERMOFORMING COMPONENTS are Attractive, Moulded in Styling Features, Durable yet Flexible, Lightweight, Less Expensive than Other Processes, Fast Time-to-Market, Design Flexibility, Seamless, Upgraded from Sheet Metal, Upgraded from Moulded Fibreglass, Bezels and Fronts, Consoles and Instrument Panels, Three-Dimensional Housings and Enclosures, Doors, Hatches, Covers and Movable Panels, Panels with Undercuts and Returns, Twin-Wall Panels, Wide Range of RAL shades and Textures etc.

Why Us?

Manufacturing Unit