Shop Floor

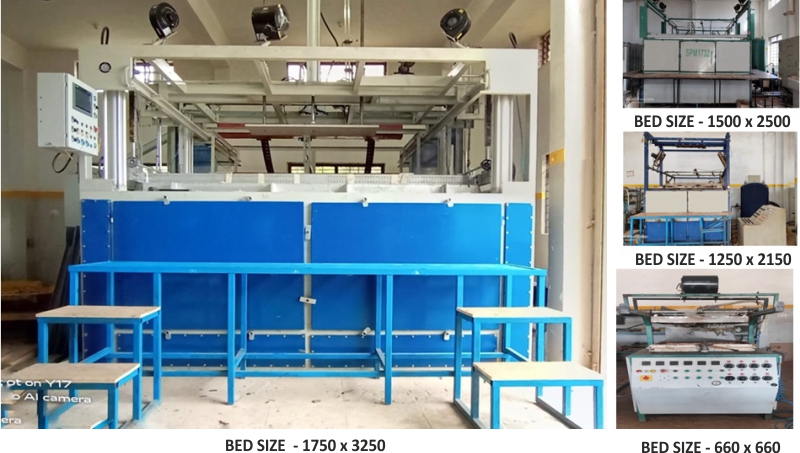

VACCUM THERMO FORMING SECTION

We have the largest forming bed size of 1750 mm x 3250 mm in North Karnataka

To meet the high demands & precise requirements of today’s Automotive industry, we have invested & set up these latest technology machines having PLC based control system.

They comprise of dual heating infrared Ceramic heaters wherein temperature can be controlled variably at different locations based on the complex design features of required components.

Different variety of materials like ABS , TPU , PP etc can be formed with the help of these machines.

INJECTION MOLDING SECTION

Injection molding is a technique used in the manufacturing of plastic products. Although it is a straight forward process there are many steps involved in creating the finished product.

Injection molding is a common manufacturing process used to create plastic products and materials. It involves inserting melted plastic into a mold cavity which has been designed into the required shape.

Many of the everyday items we see around us have been manufactured in this way – from the plastic components used in our electrical gadgets to the plastic coverings on our household appliances, and from the plastic interiors of our cars to the screw-top plastic lids on our drinks bottles – just about everywhere you look you can see a plastic object that would have been manufactured using an injection mold technique.

Machine Specification

| MACHINE NO | MAKE | CAPACITY | SHOT WEIGHT |

| IM 01 | EKOU | 300 Ton | 1000 Gm |

| IM 02 | WINDSOR POLO | 130 Ton | 300 Gm |

| IM 03 | POLOSMART | 130 Ton | 250 Gm |

| IM 04 | EKOU | 125 Ton | 200 Gm |

| IM 05 | EKOU | 130 Ton | 150 Gm |

| IM 06 | CHHATRABHUJ | 125 Ton | 80 Gm |